FACADE PLYWOOD

Definition

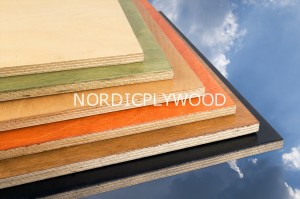

Facade plywood can be described as highly durable, highly water-and-wear resistant, easy to clean and really a trouble free product if installed and maintained correctly. Due to its characteristics it is mainly used as an exterior material. We use veneer with the format of 1220 x 2440 mm for our facade plywood which can be ordered in a wide selection of colors. The boards can be cut into any size the client wishes.

The edges of boards are dyed with a specific paint which prevents humidity from getting between the plywood layers making facade plywood waterproof. After softening the edges and sanding the plywood it can be finished by staining, varnishing or dyeing with Teknos paints. We cut our plywood with 45 degree angled corners. After the plywood boards are cut to the preferred measurement the horizontal surface should be plained.

Facade plywood boards can be attached to one another with glue, special joints (grooves have to be carved into the edges of the plywood) or visible bindings. In the case of visible bindings it is important that they are in a straight row because detaching the plywood after it has been glued or attached with screws is very hard. To hide the minor inaccuracy of installation it is recommended to place the boards completely side by side or leave a 5-10 mm space between letting the plywood’s striped edges to be seen.

EUROPLYWOOD also offers installation (also the installation of heating and carcass) and the later maintenance of facade plywood.

Field of application

As the name says facade plywood is mainly used for facades of building. It can be a substitute for wood facade and serve as a decorative construction element due to the variation of available colors.